Drums & Brake Shoes

Drums & Brake Shoes

It can be difficult to judge when you need to replace the brake drums on your semi-truck. However, there are a few important things to look out for. The best way to determine if the brake drums need to be replaced is by doing a visual inspection. You can do this yourself or send the semi-truck to a mechanic.

The brake drums should be replaced if there are visible cracks on them. We will cover this in further detail later on. You can also measure the inner diameter of the drum. If the brake surface diameter exceeds the allowable limits, the drum must be replaced.

Air system & Chambers

Air system & Chambers

It is extremely important to comprehend how the air system works on our truck. This is the only way we have to keep every part of the system working at its optimal condition. The five main components of an elementary air brake system and their purposes are:

- Compressor: to build up and maintain air pressure

- Reservoirs: to store the compressed air

- Foot valve: to draw compressed air from reservoirs when it is needed for braking

- Brake chambers: to transfer the force of compressed air to mechanical linkages

- Brake shoes and drums or brake rotors and pads: to create the friction needed to stop the vehicle

Slack adjusters

Slack adjusters

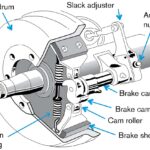

Slack adjusters are mechanical links between the brake-chamber push rod and the camshaft on cam type brakes. Slack adjusters are not used with wedge-type brakes.

Slack adjusters are used to manually (Fig. 51) or automatically (Fig. 53) maintain proper brake chamber stroke and lining-to-drum clearance during normal operation.

Slack adjusters are available in a variety of arm configurations, lengths, torque ratings and spline types.

The entire slack adjuster operates as a unit, rotating with the brake camshaft as brakes are applied or released. The most efficient braking occurs when push rod travel is held to a minimum, therefore it is important that brake adjustments are made often.